jknaus

Administrator

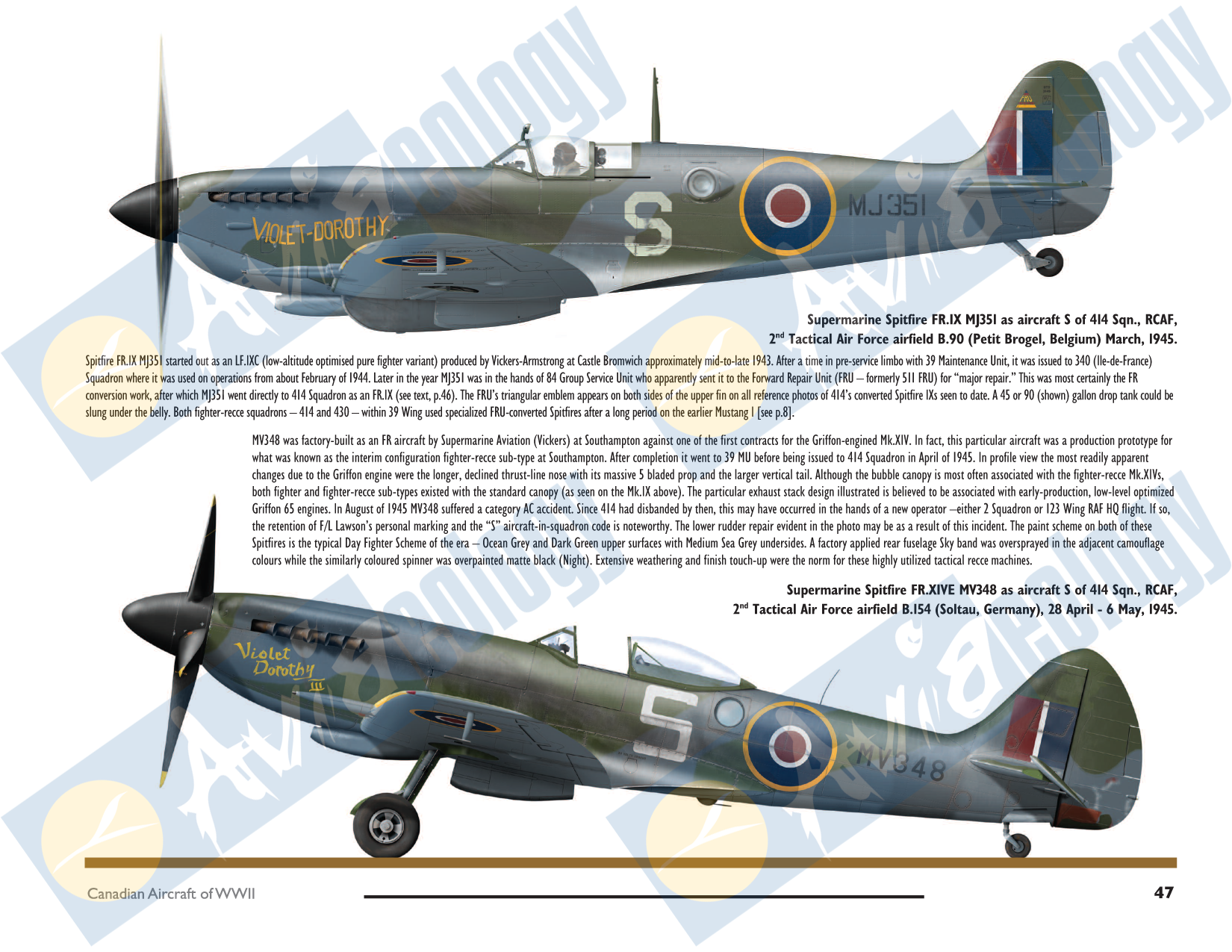

Well let the butchering begin. I decided I would attempt to build this but kind of nerve wracking taking the first cuts on an expensive kit and conversion. Nose fits really well though so quite happy. Tomorrow the tail comes off and the aft fuselage gets chopped for retracting tail wheel. This is the Tamiya Mk XVie Low Back Spitfire and Laminar Flow Designs conversion. Also to go into this I have the LFD cockpit upgrade and printed out the LFD instrument panel. I'm making Violet Doroth III flown by Squadron Leader Ken Lawson of 414 Sqn RCAF during May of 45. Although I also have markings for S/L James Prendergast of 414 Sqn who flew Lazy Lady aircraft number P.

I cant find Lawsons pic but here is Prendergast.

And here is aircraft code D. being serviced.

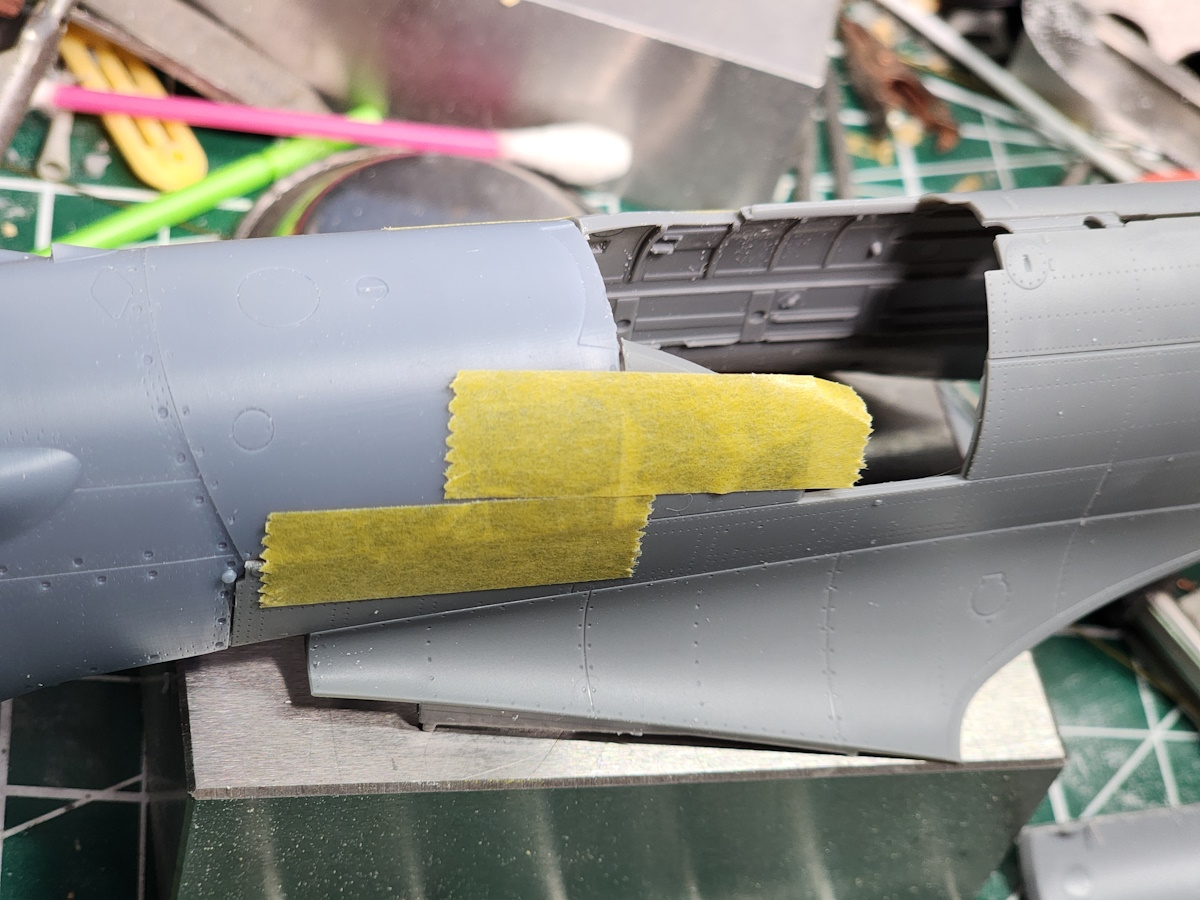

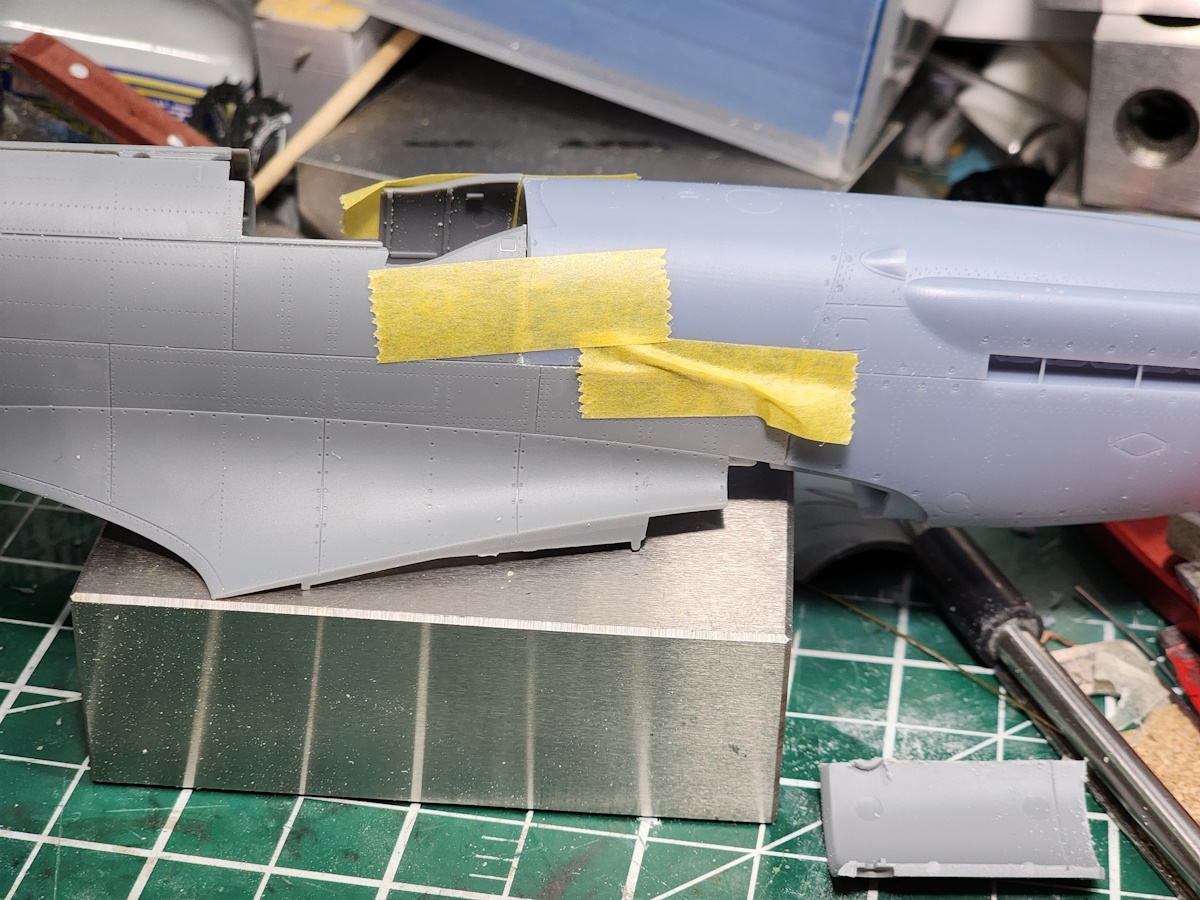

So after carefully cutting the nose free from its supports and then carefully cutting the nose of the kit, here is where I am now.

James

I cant find Lawsons pic but here is Prendergast.

And here is aircraft code D. being serviced.

So after carefully cutting the nose free from its supports and then carefully cutting the nose of the kit, here is where I am now.

James